I. Production process and required equipmen

1.crushing section

Process scraps into wood chips with drum wood chipper, and the dimension of them is 30-50 mm.

2. Pulverizing section

Seconadry size reduction, when the capacity is not large, as well as the moisture less than 45%, the wood chips from previouse section will be futher pulverized and grinded into sawdust, within 5-8mm. The capacity could be strictly affected by the moisture content

3.pelletizing section

The full process is a complete physical change. By the spinning of the main shaft, it drives the rollers of the pellet mill to push the materials into the trumpet haped holes of the pellet mill ring die, and the materials are firmly compressed into shape. There are no any chemical adeheres are applied at all.

4.cooling section

When the pellets are freshly made out of the machine, because it’s from fully physical work, the termperature is very high, thus with the help of the cooling machine, not only the pellets could be cooled down, but also it could store the pellets for a while, stressen the pressure of packing & convening sections.

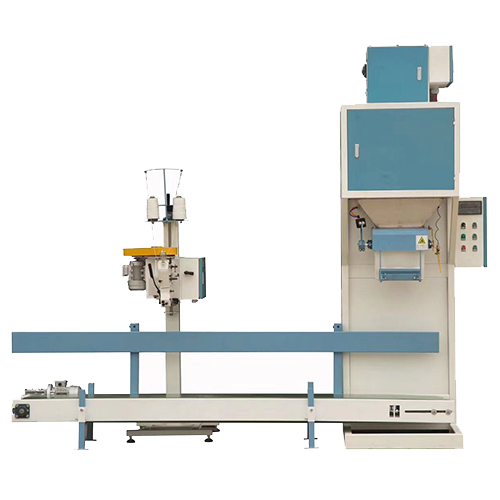

5.packing section

Under the action of the packaging machine, the pellets are packed into the bag according to the required weight, and the bag is automatically sewn. Convenient for transportation and sale.