Biomass

As global energy demand continues to grow, biomass energy, as a renewable energy source, is being widely used in industry and daily life. Biomass pellets are a new type of clean energy. By processing agricultural and forestry waste (such as wood chips, rice husks, corn stalks, etc.) into granular materials, they can be used as fuel and animal feed. The key to biomass pellet machine production technology lies in the reasonable selection of raw materials (Raw Materials) and equipment, and ensuring precise control of the production process. This article will introduce the production process, key equipment and functions of biomass pellet machines in detail to help readers gain an in-depth understanding of the production process of this environmentally friendly energy.

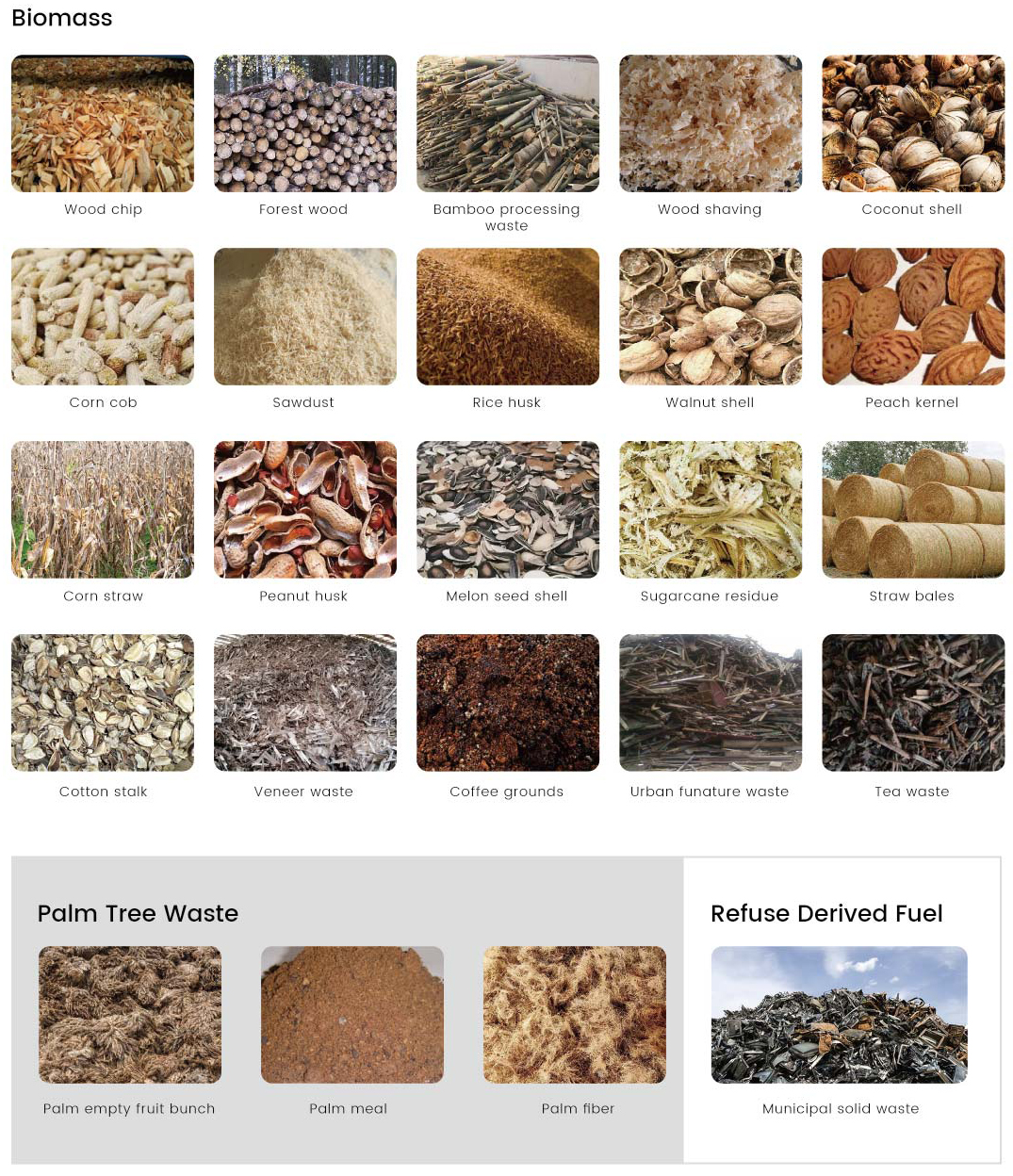

1. Raw Materials for the Production of Biomass Pellets

The raw materials of biomass pellets can be divided into crop waste and forestry waste. Crop waste includes rice husks, corn stalks, wheat stalks, etc. These raw materials are abundant and low in cost; while forestry waste includes wood chips, bark, branches, etc. These wastes are rich in organic matter and can be converted into high-calorific value biomass pellets after processing, which are suitable for heating, power generation and animal feed.

2. Overview of Biomass Pellet Production Equipment

In order to convert raw materials into biomass pellets, a complete biomass pellet production line (Pellet Mill Production Line) is required, which includes the following key equipment:

Hammer Mill: Crushes large pieces of raw materials into small particles for subsequent pelletizing operations.

Small Pellet Mill: Usually used in small production lines, suitable for home or small-scale production.

Triple Pass Dryer: Removes moisture from raw materials and improves the combustion efficiency of biomass pellets.

Wood Crusher: Used to crush harder raw materials such as wood into suitable particle sizes.

Drum Wood Chipper: Cuts wood to ensure that the size meets production requirements.

Packing Machine: Packs the finished pellets for easy transportation and storage.

3. Biomass Pellet Production Process

The production process of biomass pellets can be divided into several steps: raw material pretreatment, crushing, drying, pelletizing and packaging. The following are the detailed production steps:

(1) Raw material pretreatment

First, the raw materials need to be classified and cleaned. For example, for wood raw materials, impurities such as stones and iron filings are removed, and then the wood is cut into small pieces using a drum wood chipper. For other raw materials such as crop straw, preliminary processing is also required according to the size of the raw materials to ensure the smooth progress of subsequent processing.

(2) Crushing

After the raw materials are pretreated, they enter the crushing stage. The hammer mill is a key equipment in the crushing process. Its function is to crush larger pieces of raw materials into fine particles suitable for pelletizing. This process not only improves the uniformity of the particles, but also reduces the possibility of particle breakage during the production process.

In addition, for home or small-scale production, small crushers and small pellet mills are more suitable because they are simple to operate and highly efficient, and can meet the daily needs of biomass pellets.

(3) Drying

The crushed raw materials usually contain a certain amount of moisture and need to be dried to ensure the combustion performance of the final product. The Triple Pass Dryer is a commonly used drying equipment. Through the design of multiple cycles, it can effectively remove moisture from the raw materials and ensure that the moisture content of the raw materials meets the production standards of biomass pellets.

(4) Granulation

The dried raw materials enter the pellet mill through the conveying system for pelleting. The pellet mill presses the crushed raw materials into small pellets under high temperature and high pressure. Here, different types of pellet mills can be selected according to production needs. Small production lines usually use small pellet mills, while large production lines are equipped with more powerful equipment to improve production efficiency.

In animal feed production, dedicated animal feed pellet machines are usually used. These equipment can produce pellet feed suitable for livestock nutritional needs according to different feed formulas.

(5) Cooling and screening

During the pelleting process, the pellets are squeezed under high temperature and high pressure, and the temperature is high. The newly formed pellets need to be cooled to facilitate subsequent packaging and storage. The cooler can quickly cool the high-temperature pellets to room temperature and remove some moisture in the process. After cooling, the pellets will pass through a screening system to remove unqualified debris and fine particles to ensure the quality of the final product.

(6) Packaging

The cooled biomass pellets enter the packing machine for automatic packaging. The packaged products are easy to transport and store, and can prevent the pellets from getting damp or contaminated. Different production lines can choose automatic or semi-automatic packaging machines, which can be flexibly selected according to production needs and capital budget.

4. Functions and features of key equipment

In the entire production process, the role of several types of equipment is particularly important:

Hammer Mill: It is the first step in pellet production, which makes the raw materials uniform and fine by crushing.

Triple Pass Dryer: It effectively removes moisture and improves the combustion performance of pellets.

Small Pellet Mill: It is suitable for home and small production, easy to operate and low energy consumption.

Wood Crusher and Drum Wood Chipper: It is used to pre-treat harder wood raw materials to ensure that the raw material size meets production requirements.

Packing Machine: Automatically pack the finished product for easy storage and sale.

5. Application and future prospects of biomass pellets

As a clean and renewable energy source, biomass pellets have been widely used in heating, power generation and animal feed. As a fuel, it burns cleanly, has low ash content, and can reduce the consumption of fossil energy; as animal feed, biomass pellets are rich in nutrients and easy to store and transport, especially in the breeding industry.

With the implementation of environmental protection policies and the adjustment of energy structure, the market prospects of biomass pellets are very broad. Through reasonable production processes and the application of advanced equipment, the production efficiency and quality of biomass pellets are constantly improving. In the future, the automation level of biomass pellet production lines will be further improved, and the equipment will be more energy-saving and environmentally friendly.

Conclusion

The production technology of biomass pellet machines can not only effectively utilize agricultural and forestry waste, but also make important contributions to energy conservation, emission reduction and environmental protection. By precisely controlling each production link and selecting appropriate equipment configuration, biomass pellet production can achieve low-cost and high-efficiency operation to meet the market demand for clean energy and high-quality feed.