Features: 1.It adopts welded-steel plate construction, machine is embedded for seal. 2.Forged hammers has symmetric homogeneous permutation, small vibration without blind angle, large crushing friction area. 3.It contains two rotors and they rotate relative to each other, which leads to better performance compared with single shaft type. 4.Operating door has safety interlock to make sure it can not be opened when running.

Product Introduction:

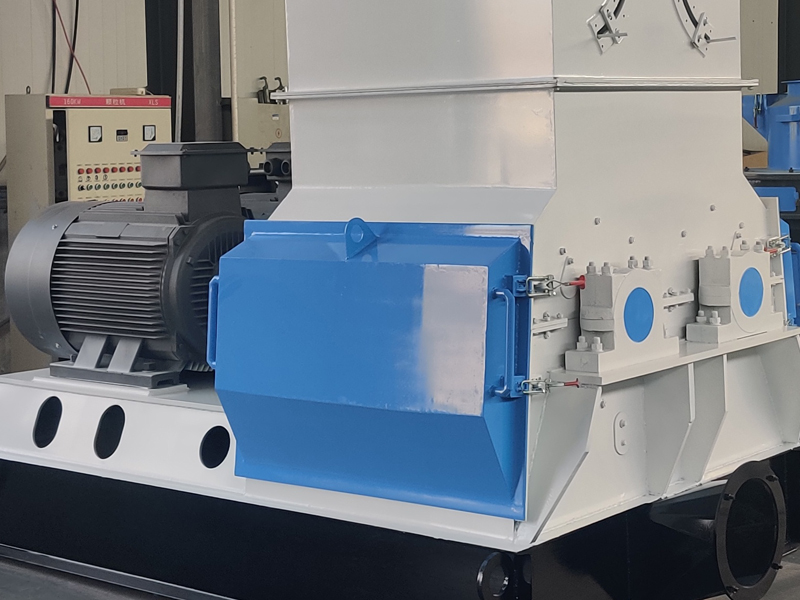

Hammer mill grinding machine is a device that uses high-speed rotating hard and high-toughness alloy hammers to beat and crush materials to produce small-sized materials. The hammer-type high-efficiency hammer mill is widely used in various industries such as biomass fuel, pharmacy, chemical industry, scientific research, feed organic fertilizer, breeding, etc. It is suitable for grinding various forestry and agricultural wastes such as biological straw, straw, wood chips and wood branches. The high-efficiency hammer mill has become an important auxiliary equipment in the production process of biomass briquette because of its high speed, good stability, collective sturdiness and durability, simple operation and maintenance, and satisfactory energy-to-output ratio.

Specification:

| Model | GXPSS80*100 |

| Capacity | 5-8 t/h |

| Power | 110*2 kw |

| Hammer Qty | 192 pcs |

| Dust collector bag number | 96 pcs |

| Cyclone | Φ1800 mm |

| Weight | 5200 kg |

| Dimension | 2800*1800*2570 mm |

Features:

1.It adopts welded-steel plate construction, machine is embedded for seal.

2.Forged hammers has symmetric homogeneous permutation, small vibration without blind angle, large crushing friction area.

3.It contains two rotors and they rotate relative to each other, which leads to better performance compared with single shaft type.

4.Operating door has safety interlock to make sure it can not be opened when running.