Features: 1.The hammer mill will be passed by the dynamic balance testing, and the weight difference of each group of hammers dose not exceed 1 gram, so as to ensure the stable operation of the machine. 2.The bearing seat is made of bearing steel, which is large and wide to ensure stable operation. 3.The discharging port of hammer mill is higher, and the material is not easy to be blocked. 4.The raw material of hammers is tungsten carbide welding. The hammer is thick, and the crushing effect is better.

Product Introduction:

Hammer mill is one wood crusher machine,which is used to produce sawdust. The finished size of saw dust is 3 to 5 mm. Materials that can be processed by the hammer mill include wood chips, shavings, agricultural straw, rice husk, peanut shell, wood branches,etc.

Specification:

| Model | GXP65*75 |

| Cpacity | 1-3 t/h |

| Power | 75 kw |

| Hammer Qty | 72 pcs |

| Dust collector bag number | 48 pcs |

| Cyclone | Φ1200 mm |

| Weight | 2000 kg |

| Dimension | 2550*1100*2300 mm |

Features:

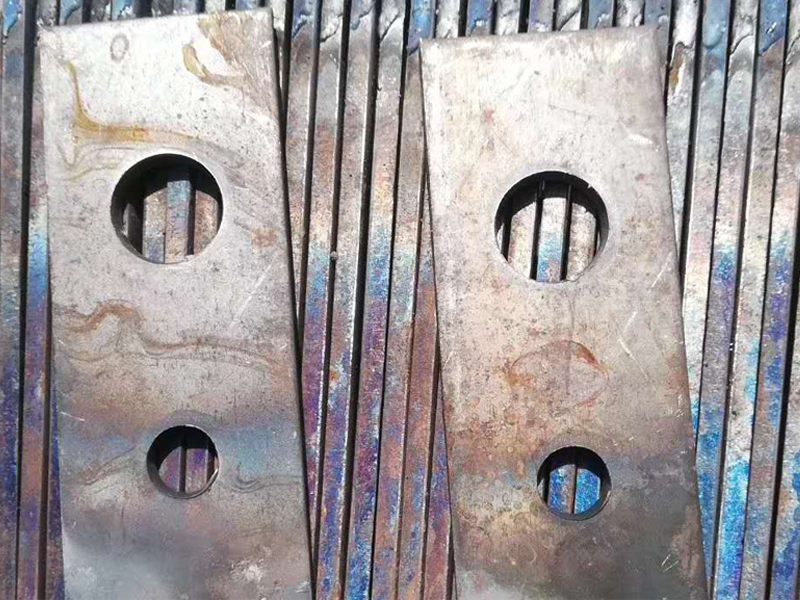

1.The hammer mill will be passed by the dynamic balance testing, and the weight difference of each group of hammers dose not exceed 1 gram, so as to ensure the stable operation of the machine.

2.The bearing seat is made of bearing steel, which is large and wide to ensure stable operation.

3.The discharging port of hammer mill is higher, and the material is not easy to be blocked.

4.The raw material of hammers is tungsten carbide welding. The hammer is thick, and the crushing effect is better.