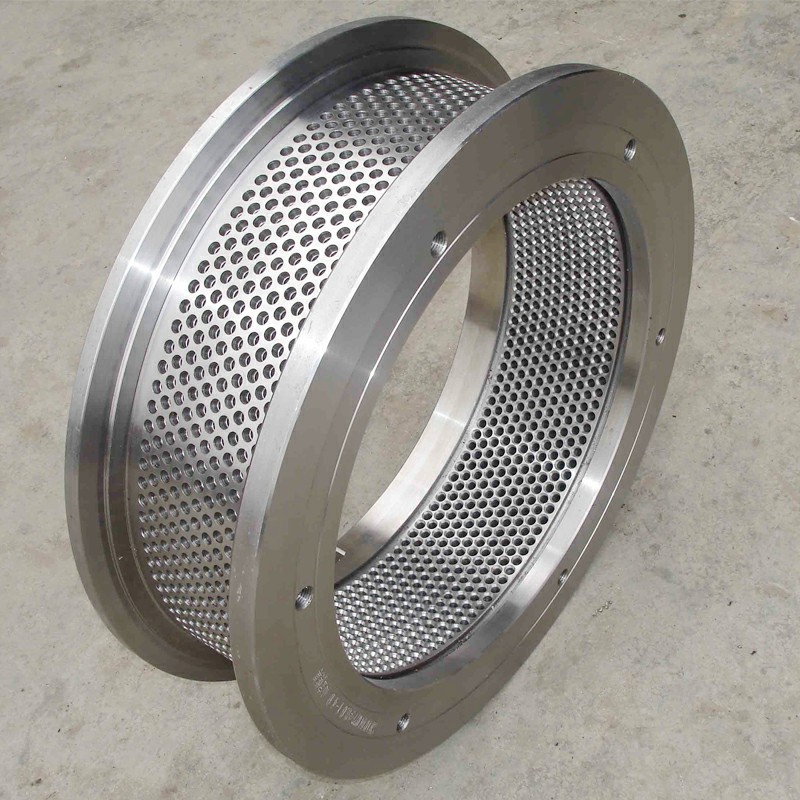

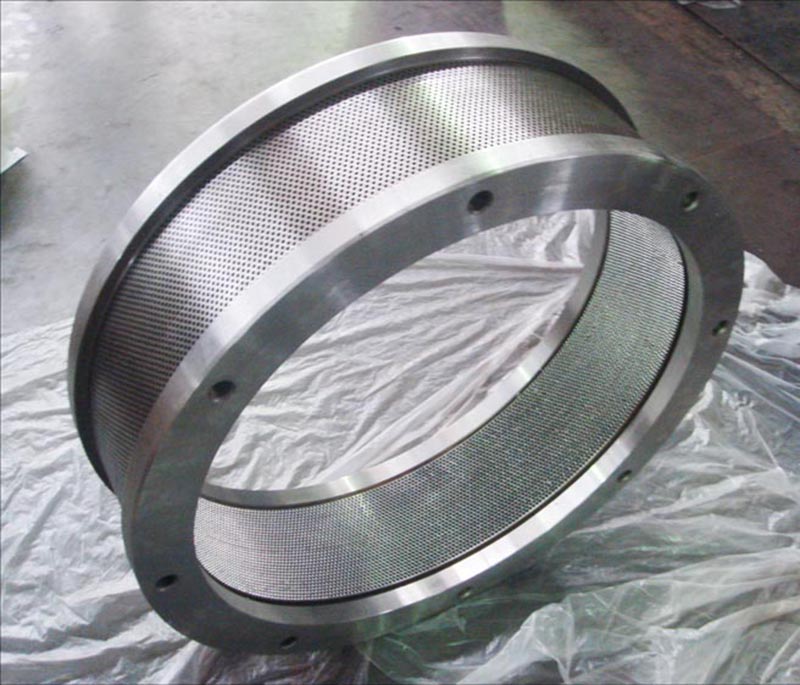

We can guarantee: • High quality Alloy & Stainless Steels as raw material, processed with extremely precise manufacture; • Perforation and mirror polishing of holes; • Vacuum heat treatment, making the die much more durable and better pellet quality; • Minimum die deformation after heat treatment; • Test and control before delivery • All dies are through hardened to 55-60HRC.

| Buhler ring die series | ||||

| Item NO. | Size | Material | HRC | Hole Diameter |

| Buhler 304.58 | 381-304-58 | Stainless Steel(X46Cr13) | 55-60 | φ4-20mm |

| Buhler 304.78 | 381-304-78 | Stainless Steel(X46Cr13) | 55-60 | φ4-20mm |

| Buhler 420.108 (DMFJ) (DPCB) | 489-420-108 | Stainless Steel(X46Cr13) | 55-60 | φ4-20mm |

| Buhler 420.138 (DFPB) (DFPC) | 489-420-138 | Stainless Steel(X46Cr13) | 55-60 | φ4-20mm |

| Buhler 520.138 (DPBA) (DPUC) | 610-520-138 | Stainless Steel(X46Cr13) | 55-60 | φ4-20mm |

| Buhler 520.178 (DPBS) | 610-520-178 | Stainless Steel(X46Cr13) | 55-60 | φ4-20mm |

| Buhler 660.138 (DPAB) | 790-660-138 | Stainless Steel(X46Cr13) | 55-60 | φ4-20mm |

| Buhler 660.178 (DPAA) | 790-660-178 | Stainless Steel(X46Cr13) | 55-60 | φ4-20mm |

| Buhler 660.228 (DPAS) | 790-660-228 | Stainless Steel(X46Cr13) | 55-60 | φ4-20mm |

| Buhler 660.265 (DPHD) | 790-660-265 | Stainless Steel(X46Cr13) | 55-60 | φ4-20mm |

| Buhler 900.178 (DPGC) | 1030-900-178 | Stainless Steel(X46Cr13) | 55-60 | φ4-20mm |

| Buhler 900.228 (DPGB) | 1030-900-228 | Stainless Steel(X46Cr13) | 55-60 | φ4-20mm |

| Buhler 900.300 (DPHE) | 1030-900-300 | Stainless Steel(X46Cr13) | 55-60 | φ4-20mm |

The good thing for using famouse brand machine, is that you could get their good quality and services; the other side, their spare parts are really really expensive, and need much more time before you receive it. That's why we could offer you a better chioce!

With 10 year experience in Pellet Machinery Industry,

MACREAT is proud to introduce that we could provide you with any ring dies from any brand!

We can guarantee:

• High quality Alloy & Stainless Steels as raw material, processed with extremely precise manufacture;

• Perforation and mirror polishing of holes;

• Vacuum heat treatment, making the die much more durable and better pellet quality;

• Minimum die deformation after heat treatment;

• Test and control before delivery

• All dies are through hardened to 55-60HRC.

Some salient features of our dies:

• easy production start-up's

• high productivity

• long life.