We can guarantee: • High quality Alloy & Stainless Steels as raw material, processed with extremely precise manufacture; • Perforation and mirror polishing of holes; • Vacuum heat treatment, making the die much more durable and better pellet quality; • Minimum die deformation after heat treatment; • Test and control before delivery • All dies are through hardened to 55-60HRC.

| Ring Die Pellet die Pellet Mould Matrix For Pellet Machine Andritz PM | ||||

| Pellet mill type | Working area | Number of rollers | Max. power 50Hz | |

| Gear-driven | CM2 | SQ.IN | Std | KW |

| PM615W | 3016 | 468 | 2 | 160 |

| PM615XW | 3581 | 555 | 2 | 160 |

| PM717W | 4178 | 648 | 3 | 355 |

| PM717XW | 5498 | 852 | 3 | 355 |

| PM30 | 3600 | 558 | 2 | 355 |

| PM919W | 5432 | 842 | 3 | 560 |

| PM919XW | 7147 | 1108 | 3 | 560 |

| PM919TW | 8577 | 1329 | 3 | 560 |

| PM1219W | 11400 | 1767 | 3 | 560 |

| PM1219XW | 14313 | 2290 | 3 | 560 |

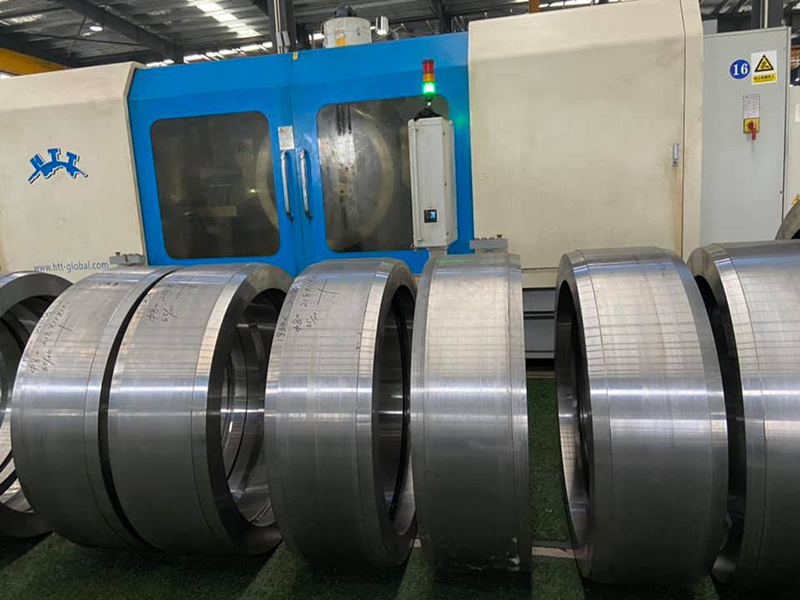

With 10 year experience in Pellet Machinery Industry,

MACREAT is proud to introduce that we could provide you with any ring dies from any brand!

We can guarantee:

• High quality Alloy & Stainless Steels as raw material, processed with extremely precise manufacture;

• Perforation and mirror polishing of holes;

• Vacuum heat treatment, making the die much more durable and better pellet quality;

• Minimum die deformation after heat treatment;

• Test and control before delivery

• All dies are through hardened to 55-60HRC.

Some salient features of our dies:

• easy production start-up's

• high productivity

• long life.